Synthetic Supercritical Geothermal

A New Breakthrough: Carbon-Free, Scalable, Renewable Energy

WHO WE ARE

The GeoX Team

GeoX's leadership consists of diverse, highly experienced experts in oil and gas drilling. The team includes Fortune 500 drilling operations managers, drilling and reservoir engineers, geophysicists, turbine engineers, metallurgists, chemists, and thermodynamicists who bring a wealth of knowledge and industrial expertise to the company. Geox’s oil and gas team has been responsible for managing some of the most complex oil and gas drilling projects globally. These projects have included both deepwater and land wells with high-pressure and high-temperature conditions, some valued at billions of dollars for firms such as Shell, ExxonMobil, and ConocoPhillips.

In 2019, the National Renewable Energy Laboratory (NREL) testified to Congress that the growth of geothermal energy would depend on utilizing the oil and gas industry's well engineering expertise, truncated drilling time frames and project management. This is because geothermal energy projects are primarily drilling projects, and the oil and gas industry currently drills 70,000 wells per year with a success rate of 99.99%, attributed to their meticulous risk mitigation strategies in the design and execution of operations.

Synthetic Supercritical Geothermal demands the same drilling fundamentals and expertise as in the most complicated oil and gas projects, qualifying us to be the ones to bring GeoX power stations into reality.

-

Andrew Fleming

FOUNDER & CEO

Fortune Global 500 deep water oil and gas drilling operations. Responsible for global deep water billion-dollar HPHT drilling projects & assets & HSE. 30 years of leadership in 16 countries, Ophir, Conoco Phillips, Essar, Zapata. BSc Eng/S.

-

Greg Szutiak

HEAD OF ENGINEERING AND TECHNOLOGY

Global 500 oil & gas well engineering & operations. Responsible for global engineering projects/assets, with over 23 years of leadership. Led commercialization of many drilling and completion technologies within Shell & Baker Hughes. BSc Petroleum Engineering.

-

Kumar Ampapathini

CFO

Expertise in Mergers & Acquisitions, FP&A, Strategic Planning, Business Development, Financial Modeling, Fundraising, and Automating Financial and Accounting Processes. Masters in Business Administration and Computer Science.

-

Heath Johnson

VP OF LAND, CPL, MLS

Certified Professional Landman, Master’s in Oil, Gas, and Energy Law. 18+ years of experience in the energy industry advising companies on complex Land, Legal, and Business Development matters.

HOW IT WORKS

Drilling For A New Era

Terawatt Renewable Energy

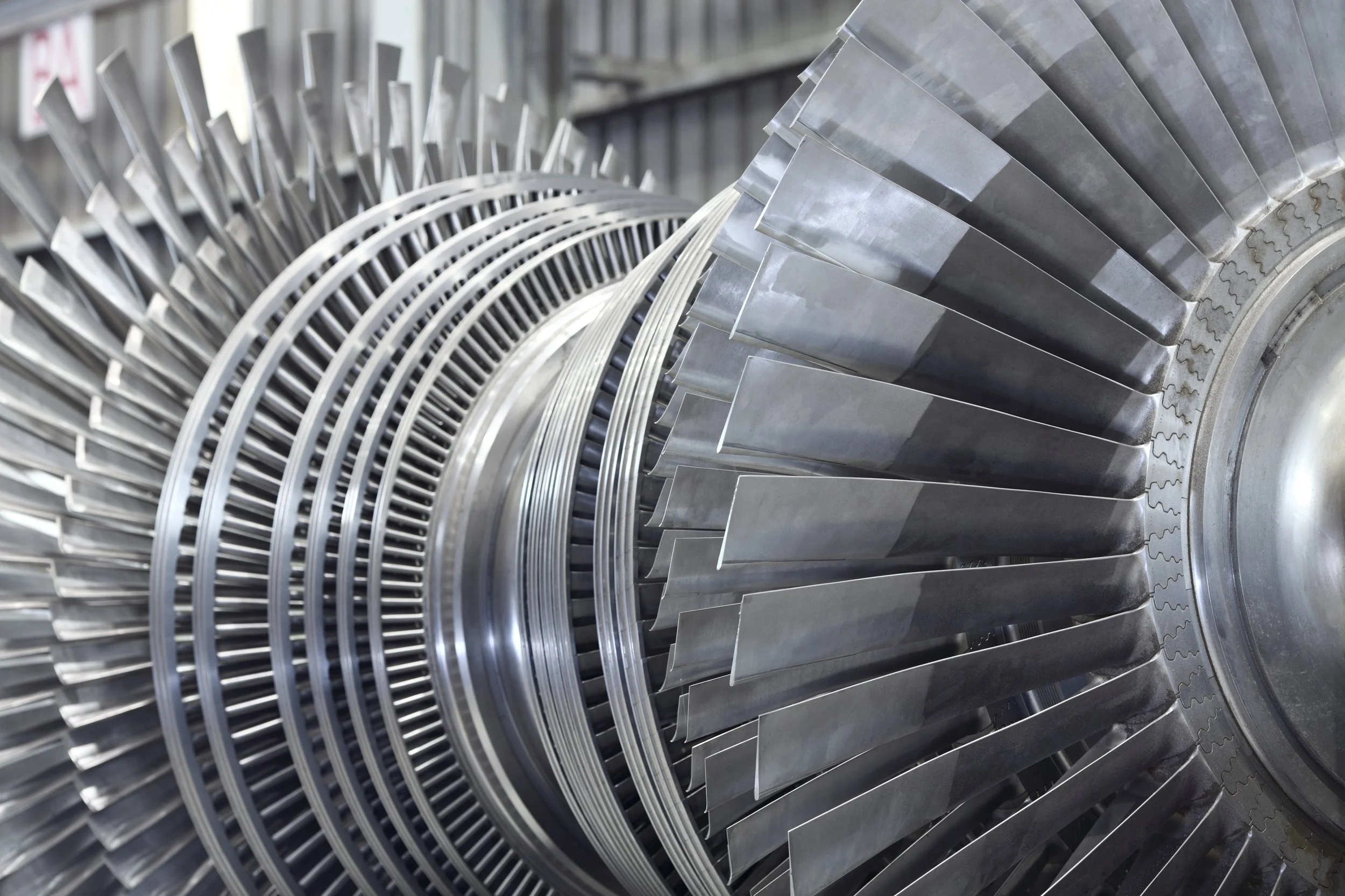

GeoX's Supercritical 850F heat exchangers are installed by drilling into Supercritical formations. Water is circulated into the heat exchanger and then brought to the surface to power our steam turbines, delivering continuous renewable power throughout the year.

Reinvented Oil & Gas Technology

GeoX has developed a new era of drilling technology IP, giving the operator power to drill into 850F formations. These formations temperatures are so hot that traditional oil and gas tools will not operate. GeoX’s new metallurgy and chemistry technology makes it possible to drill into these 850F rocks that have cooled from magma.

100% Uptime

GeoX delivers energy with 100% uptime by switching to standby wells when needed for routine maintenance. — 24 hours a day, 365 days a year. Wind and solar only average around 25% uptime, with GeoX, 100% renewable year-round power is finally possible.

Standardized Design

GeoX's standardized power stations have a significantly lower levelized cost of electricity (LCOE) compared to other renewable energy sources, as well as carbon and nuclear technologies. We eliminate costly traditional geothermal designs that take over 10 years and extraordinary costs to complete and maintain.

Leveraging Unique Materials & Chemistry

GeoX utilizes unique patent-pending leveraged materials and chemistry technology, thermally stimulated reservoir heat exchanger, and its standardized power station IP designs, manufactured in advance, then shipped and installed in a truncated time frame, up to 10X faster.

GeoX’s first principle designs will replace Terawatt Carbon Power Plants

and eliminate 100M tons of CO2 in 15 years and 73% of PM2.5 within 50 years.

WHAT WE DO

Vertically Integrated Turnkey Power Stations

-

Geological Pre-Planning

GeoX's geophysicists evaluate and select the best possible sites for well placement and drilling.

-

Heat Exchanger System

GeoX's engineers construct heat exchangers used to circulate geothermally heated energy to surface to drive the turbines.

-

Standardized Fabrication

GeoX delivers standardized, prefabricated, modular geothermal power stations quickly.

-

System Installation

GeoX's field operation engineers install a power station and connect it to the grid.

-

Acceptance Testing

GeoX performs exhaustive acceptance testing of the heat exchanger and power station.

-

Production & Maintenance

GeoX's maintenance engineers manage and run the power station 24 hours a day, 365 days a year.